Tumturbo Oil-Free

Touch-Free™

Tamturbo® air compressor direct-drive turbo technology is centred around a few unique principles. At the heart of every Tamturbo® oil-free air compressor is our patented capacity control and operating system, operating the 3-stage compressor core with the help of industry-leading Variable Speed Drives (VSD).

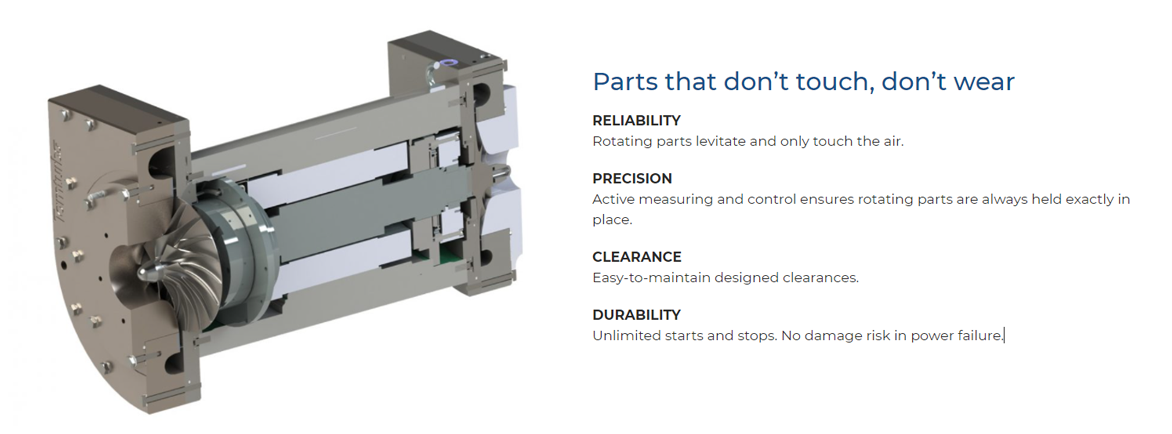

Tamturbo® proprietary Active Magnetic Bearings (AMB) are the key to the Touch-Free™ technology. By providing friction-free rotation with zero drag or metal-to-metal contact, our components won’t ever wear or break down. The AMBs react instantly, eliminating vibration completely. Self-protecting levitation also prevents damage in the event of a power failure inside your facility, as power stored in the rotation and in capacitors keeps the bearings energized until the motor slows down and stops. Over hundred thousand AMB units in HVAC, oil and gas fields, deep-sea gas pumps and other tough uses have proven our product’s technology, maturity and superiority in demanding applications.

Touch-Free™ Air – compressed air as a service

Now there’s a better way to achieve compressed air. With Touch-Free™ Air, you won’t have to touch a thing. Not your compressor. Not your production schedule. Not even your working capital. Because at Tamturbo, it’s no longer about the air compressor, it’s all about the air. Touch-Free™ Air literally means you only pay for providing the air you use. Not the air compressor, the maintenance or the worries that go with it. We’ll set up the right system for your facility, and you won’t have to touch it. You only get what you want: an uninterrupted supply of 100% oil-free air, at the lowest cost per unit.

Touch-Free™ Air helps concentrate on core business – both from economical and operational perspective

Tamturbo Touch-Free Air solution was delivered to support Componenta Corporation’s sustainable development and better cost management of compressed air production.

Tamturbo® Touch-Free™ Air- compressed air service agreement means that Componenta didn’t need to invest in the new equipment. They only pay for the actual consumed compressed air. Tamturbo takes care of everything – the System Load Control, Movable Compressor Room and their service and, of course, the compressor. A truly care-free package

”The Touch-Free™ Air contract offered by Tamturbo has lowered the barrier to upgrade the compressed air systems with technology from this millennium without new investment or unpleasant and unexpected maintenance costs in the future. This further helps us to manage the cost of compressed air production. We only pay for the air we use. By improving the compressed air system, we have been able to significantly reduce the cost of production. Additionally, we were able to connect our old compressors into the same Tamturbo System Load Control. This makes control of the compressed air production simple. With the system we have adequate airflow in all consumption situations in the most cost-effective way,” says Componenta’s Maintenace Manager Petri Kulmala.

Industrial compressed air solutions

Tamturbo Oil-Free VSD air compressors offer high efficiency and outstanding savings in both energy and maintenance. Learn how our Touch-Free™ turbo compressors are utilized in a variety of industrial compressed air applications.

- Manufacturing industry

- Textile industry

- Electronics industry

- Automotive industry

- Pharmaceutical and medical

- Pulp and paper industry

- Food and beverage industry